Wednesday, March 5, 2014

Field Trip Saturday

http://www.santacruzmah.org/index.php?page=visit-us

Bring your student ID-- it will be $3 instead of $5 to get in. I wasnt expecting to have to pay at all!

After we visit the museum well go to Shens Gallery, 2404 Mission St.

http://yhst-85205485710675.stores.yahoo.net/index.html

Questions about the field trip or your table project, email me: sw@shannonwright.org.

Free Woodworking Patterns

I hadnt originally intended on making free woodworking patterns available until I started to realize how much time it takes to create a pattern from scratch. Since I usually create a pattern to run on a CNC router, it has to be in a vector graphics format suitable for cutting on a computerized machine. As such, quite a bit of time goes into making sure the geometry and formatting is just right.

As is the case with other woodworking plans, a pattern often gets used only once and then is discarded or forgotten. By making them available here, my hope is that you will find something to help you with one of your own projects. Also, vector graphics are easy to shrink, stretch, or modify into something new altogether. So even if you dont find something to meet your needs exactly, it might provide a good starting point.

If you dont already use a program like Adobe Illustrator, CorelDRAW, or even AutoCAD, I encourage you to check out a free vector graphics program like Inkscape. Vector graphics are nearly infinitely scalable and fairly easy to modify. Theyre also perfect for use in CNC routing operations, water jet or plasma cutting of metals and plastics, and even embroidery.

Heres a simple little lighthouse pattern with a border. Originally designed for use on a wooden house number, it could be adapted for nearly anything. By following the link or clicking on the picture, youll find more details and several different file formats that you can view or download.

Return from Free Woodworking Patterns

to Totally-Free-Woodworking-Plans Home

Guitar pick holder and pendant

I made my version out of mahogany and accomplished most of it on my scroll saw. Simple project, just a little tricky to make the cuts accurate, given its size.

Tuesday, March 4, 2014

Beginner Woodworking A Simple Guide

Beginning a woodworking project is very daunting, especially if you dont have a good plan to follow. A good woodworking plan is the best company for beginner woodworking projects. Finding the right woodworking plan that matches your level of expertise is very crucial. Back then, woodworking is more of a hobby to our grandparents, and plan is not necessary. They just build whatever comes in their mind. Fast forward to todays time, woodworking plan is a must.

Things to consider before starting out a woodworking project:

Idea - getting a woodworking idea is somewhat a problem for a beginner woodworker. A good idea on what to build is the key to everything. It is a must to have an idea on project to start with. Most of the time, the idea just sparks out of your mind due to necessity.

Plan - be ready to start your project with a good plan on how to finish it to save time and money. Expect to make a few mistakes and blunders on the way, but make this as a learning process mistakes.

Ask yourself these questions before starting a woodworking project:

What am I going to build? What would be my benefit in building it?

Does my skill match what I am going to build?

Is there a space where I can work on without being interrupted?

Will time be a problem when I start this project? How much time do I need?

Do I have the financial resources to buy the materials and tools needed for the project?

Answering these questions will equip you in starting your project, with a goal of finishing it.

Get a good woodworking plan - as soon as you decided on what to build according to the skills you have, a good woodworking plan is needed. This is the step-by-step instructions on how to build your project. A good woodworking plan also gives you all the list needed to finish your project, like tools you will need, the materials to use and where to buy it.

Lastly, be safety conscious - this is extremely important! It is a must! It is better to be safe than sorry. Using power tools, if you have to, must be used with caution. You should also use protective gears such as safety goggles, working gloves, safety shoes, ear plugs and carpenters gown. Wearing this personal safety gadgets is a must! You never know what will going to happen, and you dont want to lose an eye or a finger from the new found hobby!

Before starting any woodworking project, you should do some reading and research. There are so many free reading resources on the internet where you can find basic information about beginner woodworking project. These are HowTo, DIY Guides, and self-help guides. There are also good books to read about woodworking from your local library.

You should also inventory all the necessary materials and tools you will use. The most frustrating of all is when you already started your woodworking project only to find out that you dont have all the materials needed for your project.

Above, are some of the absolute things that must be done by beginner woodworker. Working on a piece of wood and turn it into a beautiful product is very satisfying.

You can get a beginner to advance woodworking plan at http://beginner-woodworking.info

Amante Gorospe

Article Source: [http://EzineArticles.com/?Beginner-Woodworking---A-Simple-Guide&id=6692883] Beginner Woodworking - A Simple Guide

The Perfect Technichien

Woodworking Block

Do, when you have a woodworking slump, what do you do to break the slump? What projects get you back in the woodworking groove? I could use some ideas!

What inspires Arthur Lamon

This article is also available for download as a printer-friendly pdf.

Visit Arthurs web site, Woodbug: A Lost Woodworkers Adventures.

*****

Introduction

Im a product design graduate, and being a designer, I should be inspired at all times. That’s not quite possible; nobody is a walking pile of inspiration and that’s why there are several nifty tools to help you generate new ideas. During my studies I was trained to brainstorm and put those tricks to use, literally trained boot camp-style. Well, not literally. The tools that taught me to think like a product designer are more general so they are mainly used for solving problems, generating new product ideas and inventing things the world hasnt seen before. In woodworking, that’s not really necessary because normally it’s not about a completely new idea or product, but an interesting look at an existing product like a table, bed or a maybe a wooden flashlight. The tools I use daily for designing things in wood are simplified versions of the brainstorm techniques that are used in product development. They only have to generate a form, not a new function to save lives while being more eco-friendly and safe to use for 95% of the population.

Im a product design graduate, and being a designer, I should be inspired at all times. That’s not quite possible; nobody is a walking pile of inspiration and that’s why there are several nifty tools to help you generate new ideas. During my studies I was trained to brainstorm and put those tricks to use, literally trained boot camp-style. Well, not literally. The tools that taught me to think like a product designer are more general so they are mainly used for solving problems, generating new product ideas and inventing things the world hasnt seen before. In woodworking, that’s not really necessary because normally it’s not about a completely new idea or product, but an interesting look at an existing product like a table, bed or a maybe a wooden flashlight. The tools I use daily for designing things in wood are simplified versions of the brainstorm techniques that are used in product development. They only have to generate a form, not a new function to save lives while being more eco-friendly and safe to use for 95% of the population.In this essay I’m not going to focus on what-to-make, but on making your designs more interesting and which simple tools might help you to do so. Nevertheless, some of these tools are also applicable for what-to-make.

Step 1: Know your restrictions

Before going crazy on the design, it’s good to know your restrictions. My main source of inspiration is the function. I’m educated by the form-follows-function-principle, so if my object has to satisfy a certain function, I find it essential to let it guide me. For example, for the latest cabinet built I knew exactly what I’d display in it, so the whole cabinet is designed around that particular function. You still have enormous amounts of freedom, but there are some parameters that you should keep in consideration at all times. It’s like building a table; if a customer expects you to make a table for 8 people, make sure 8 people can sit at the table and not just 6 because you think it’s prettier. The table has to be a comfortable height so people can sit at it to start with. And don’t forget to make sure the table is strong enough for all possible uses for a table. If you do not keep these considerations in mind, the client might end up being disappointed, even if the design is something out of this world.

Before going crazy on the design, it’s good to know your restrictions. My main source of inspiration is the function. I’m educated by the form-follows-function-principle, so if my object has to satisfy a certain function, I find it essential to let it guide me. For example, for the latest cabinet built I knew exactly what I’d display in it, so the whole cabinet is designed around that particular function. You still have enormous amounts of freedom, but there are some parameters that you should keep in consideration at all times. It’s like building a table; if a customer expects you to make a table for 8 people, make sure 8 people can sit at the table and not just 6 because you think it’s prettier. The table has to be a comfortable height so people can sit at it to start with. And don’t forget to make sure the table is strong enough for all possible uses for a table. If you do not keep these considerations in mind, the client might end up being disappointed, even if the design is something out of this world. The list of considerations and restrictions is a design brief, and every possible design has to be compared with it to test if it’s on the right track. To make sure you can properly test the considerations, first you have to make them measurable. Being able to seat 8 people on the table has to be translated into dimensions for the table, the same for the ideal height. This way you can really verify your design instead of guesstimating it.

The list of considerations and restrictions is a design brief, and every possible design has to be compared with it to test if it’s on the right track. To make sure you can properly test the considerations, first you have to make them measurable. Being able to seat 8 people on the table has to be translated into dimensions for the table, the same for the ideal height. This way you can really verify your design instead of guesstimating it. If you have an easy project with just two things to keep in mind, don’t worry all too much about it, but if you have a more complicated project with lots of restrictions and demands from the client, you’d better make a real checklist so you don’t forget anything and you can easily verify your designs every time you have to make decisions. The design brief is something you can make together with the client because this way you can be absolutely sure you’re on the right track.

Although the word restriction doesnt sound like a very inspiring word, it helps me a lot in my designs through limiting the endless array of potential options. It’s very important that not everything is a possibility. Designing an object is easier when you know the functional limitations (seating 8 people) or expectations and style of the client. If you’re completely free to do whatever you like, chances are that you shut down instead of being inspired by the freedom. Nothing is as annoying as a client that lets you do whatever you want because they trust your abilities completely or because you are the designer.

Step 2: Fill that library

A great source of inspiration is looking at the world, at nature and man-made objects. That’s a free and effortless source of inspiration; you just got to be open to it. We work with natural materials, so of course you can find loads of inspiration in nature. I share the same sources of inspiration with a lot of other woodworkers:

- Furniture catalogues and furniture shops don’t only keep you updated about what’s out there and what the latest trends are, but they can also have a very inspiring effect. The Billy Bookcase of Ikea is a bit traditional, but what happens if you build one in solid walnut with bronze inlay? It might just be a new designer piece. A lot of my catalogues are from furniture manufacturers that don’t even make wooden furniture, but only use metal and plastic. It’s very inspiring to translate their designs in wood. It makes for a totally different effect and a nice start for the design process. There are an infinite amount of catalogues; all possible types of furniture, styles, materials, … Most of them include pictures of the pieces of furniture in an interior or landscape. This gives you a nice view on the impact of the piece, the dimensions in a real situation and for example what type of chairs best suit the table. Determining the dimensions might be a little difficult if you design something from scratch in a sketchbook. At least use a real example to help you decide on the dimensions you need. Once those are determined it’s a new bullet point on the design brief. If you have a client that needs something that’s not your style, it might help to browse a catalog with furniture in his style.

- Woodworking books and magazines are stuffed with new techniques and inspiring projects from readers. Step-by-step explanations of projects could be very inspiring because you see how others work. You don’t just learn new techniques but it challenges you to apply those techniques in other designs. If you are a novice woodworker wanting to try lamination, why make a cutting board like everyone? Make a birdhouse from laminated scraps and you instantly have a modern art birdhouse. Unless you’re in desperate need for a cutting board, like I was last week.

- The internet. I love books, magazines and catalogs because those are well-arranged. This can’t be said about the internet which is absolutely replete with information that it’s more frightening than inspiring. While there’s just too much information, there are also wonderful tools on the internet to organise all this information into manageable chunks. The one I use all the time is Pinterest and I’m absolutely loving it! I mainly follow boards that have somewhat to do with wood and interior design, so every day I have truckloads of pictures right on my homepage, all somewhat my style and ready to inspire. I just have to look at them in the right mindset. This is one of the tools that is also very useful to find inspiration on ‘what’ to make, because daily I stumble upon things I haven’t even thought about making in wood, like a USB-stick or an iPhone cover. Woodworking is big on Pinterest, so it’s also a great source of inspiration for shop made tools, joinery, fancy hardware and tutorials about every aspect of woodworking.

So after a while your head is one big library full of things youve seen before, in books, magazines, the internet, interiors and in nature... That big library is where all your ideas come from, if you like it or not. Every idea you come up with is some sort of combination of the things that are stored in your library. Over time, all the things youve seen before are mixed together and when you are designing something youre just putting the bits and pieces together. A handle of a cabinet youve seen before, placed on a cabinet door of OSB because youve seen design objects made of OSB before and it looked cool. The door is round because youve seen a round window in ships which also look crazy and its just the look youre after for the cabinet. You might think its an original idea, but in fact its an original combination of existing ideas. Being good at coming up with original combinations in fact means being trained in making those connections. You can train yourself just by challenging your own designs and becoming more experienced by doing it. However there are tools that can help you, Ive listed the ones I use the most below.

Step 4: Tools to get the most out of your library

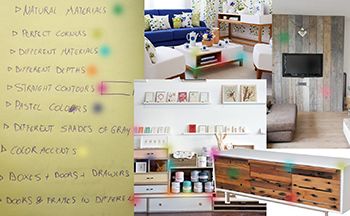

The point of the design process is to make things interesting. A box might just be a box, but if you want to make it exciting, there are a few tricks to do so. Making simple things interesting is easily done by making some straight lines into curves or including some color accents or nifty things like dowels or splines. If you have a complex design most of the times it’s already interesting because of its complexity, for example because of the different materials, the joinery, the large amount of detail,… If you have a very simple design, it might be awesome because of its simplicity. The problem area is in the middle; when your design is not very simple and not very exciting. You can choose if you want it to be more clean and simple or extremely interesting and complex.

This tool is also applicable if you have to design and build a piece of furniture for a customer that has a different style than what you’re used to. Just look at the furniture he loves, either pictures he found online for inspiration, or the furniture he already has in his house and do the same exercise.

The last thing you need to do when using mood boards is check if your new design fits the bill. You do that by placing your design on your mood board and it should blend in perfectly. If it doesn’t, go back to the drawing board.

The last tool I’ll describe here is one I use to make existing designs more original. It’s just a list of ‘what ifs’; when you have an idea in your head, challenge it with some questions like ‘what if it was bigger?’, ‘what if it was smaller?’, ‘what if it had hair?’… This tool is very useful to challenge your own designs and make them more interesting. Imagine you’re making a desk lamp, how cool would it be if you took your design and just scaled it to a floor lamp without altering the proportions? With asking a simple ‘what if’-question you just came up with the awesome idea to make a gigantic desk lamp with 4x4’s and M24 bolds. Isn’t that way cooler than the millionth desk lamp? What if you add a splash of color? If you want an original and modern table, you don’t have to make a modern design, an 18th century table will do just fine. Just paint one of the legs bright pink and all of a sudden it’s a modern design-piece. You can find an overview of 100 challenging and inspiring ‘what if’-questions in this slideshow:

Last but not least: keep a sketchbook! Dont sketch or write on loose papers because they will get lost or thrown away. It might be very inspiring to go through a sketchbook of 10 years ago, a year ago, or a week ago... Its not because an idea didnt make it for that project that its bad or that certain things cant be implemented in your new designs. And if you have a sketchbook, you should sketch while designing. Don’t feel bad if you’re not the best at drawing, nobody cares because you’re making amazing stuff in wood! But for designing those pieces of furniture, sketching is essential, so grab a pencil and go wild.

Last but not least: keep a sketchbook! Dont sketch or write on loose papers because they will get lost or thrown away. It might be very inspiring to go through a sketchbook of 10 years ago, a year ago, or a week ago... Its not because an idea didnt make it for that project that its bad or that certain things cant be implemented in your new designs. And if you have a sketchbook, you should sketch while designing. Don’t feel bad if you’re not the best at drawing, nobody cares because you’re making amazing stuff in wood! But for designing those pieces of furniture, sketching is essential, so grab a pencil and go wild.Monday, March 3, 2014

DVD CD Storage Cabinet

I was bummed that she only wanted a simple shelf, because I had come up with a kinda clever way of locating the adjustable shelves to fit various combinations of CD?s and DVD?s. Although I never had a chance to actually build the original shelf, Im publishing it here for those who might find it useful.

Material There isn?t much to say about materials. It?s designed with the same white melamine as the DVD cabinet, with white PVC edge banding. As with many of the projects youll find here, it could also be built out of plywood or even solid lumber.

I did learn something new about edge banding while designing the DVD-CD storage cabinet and building the DVD shelf. Most of my experience with banding has been operating automatic glue pot edgebanders in a commercial shop. During my very first job in a cabinet shop I also had some exposure to a simple table-top hot air bander, but that?s about it.

Recently I bought a used Virutex hand-held hot air edgebander (apparently the same machine is marketed under the Grizzly brand name). I?m accustomed to high quality PVC edge banding and was quite disappointed to discover that virtually all of the pre-glued edge banding on the market is cheap, lightweight vinyl. No wonder hot air edge banding has such a poor reputation!

I contacted my favorite edge banding supplier, Frama-Tech, and they are able to pre-glue any of their stock PVC colors for a small fee. That?s pretty awesome considering they?re incredible at matching even the most obscure laminate color. Of course my first order of PVC was white for the DVD-CD storage cabinet but it could have been just about any color I wanted.

I?m used to 15/16? edge banding and it worked very well in the Virutex bander. Having a bit of extra width was helpful in making sure it completely covered the edge of the board when my hand wasn?t running very steady. I used a FastCap Quad Pro Trimmer on the edges and a Flush Cut Trimmer for the ends. It went very quickly and you can?t tell the difference between the hand-held bander?s work and that from a $25,000 automatic glue pot bander!

Hardware Other than some small size differences, the major difference between the original DVD-CD storage cabinet and the plain old DVD shelf is in the shelf pin hole location and hardware. Initially, I wanted the CD storage shelf to be configurable for several combinations of CD?s or DVD?s. Regular 32mm system holes don?t always line up nicely for storing items of a real specific size. So I placed holes in a modestly sized cabinet such that the resulting shelf spacing would be a ?perfect? fit for storing CD?s, DVD?s, or VHS cassettes.

In the original design I had figured on using a low profile, concealed shelf support. The main purpose for this was to allow the shelf to be centered on the pin holes rather than sitting above the holes on shelf pins. I also liked the clean look of no exposed shelf supports. This requires slot to be cut in the ends of the shelves to conceal the shelf support.

When I switched to the simple DVD shelf, I also simplified the construction by eliminating the concealed support in favor of an angled steel shelf support. The angled support didn?t require the extra groove in the ends of the shelves, but still centered the shelf on the pin holes. I left the concealed support in the original DVD-CD storage cabinet plans just so you could see a nice alternative method for supporting adjustable shelves.

Drawing File Even though the DVD shelf design turned out nice, I still like this design better. Hopefully you?ll enjoy it too. You can view the drawings by clicking on the link below. If youd like to download a copy to your computer, right click then "save-as". Either way, youll need the Adobe reader to view the file.

View or Download "DVD-CD Storage Cabinet Plans"

Return from DVD-CD Storage Cabinet

to Furniture Plans

Click Here and Start WoodWorking

Wall mounted storage cabinet

This wall-hung cabinet holds nearly as much as the wall shelves I had been using for years, but takes up far less room. Now I can consider the possibilities for all this freed up space!

The shelves in this cabinet are 4 1/2" deep, just enough to store quart sized cans of stain or paint as well as the taller, narrower cans of thinners and wipe-on polys. The space between the upper shelves is 8", perfect for storing cans of spray paints and finishes. I used about a half sheet of 1/2" plywood for the entire cabinet. (See plans for cutting diagram.)

I designed this cabinet to fit together using dadoes and rabbets that I cut on one board all at once using a stack of dado blades on my table saw. No need for time consuming router set-ups. Of course, you could also cut these with a router if you dont have access to a dado set. An even easier option would be to put the whole thing together using pocket screws.

Free plans

- WWMM wall mounted storage cabinet (pdf)

- SketchUp file

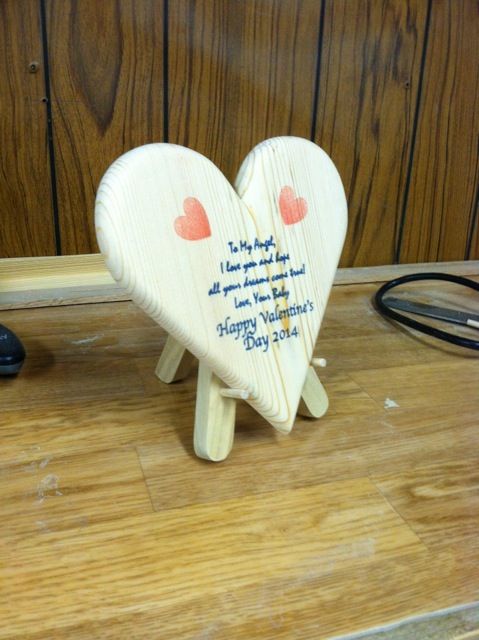

More Valentine heart ideas and project preview Its a heart

Sunday, March 2, 2014

Cottage Living Inspired Ledge

Used Wood Working Equipment Wooden Ideas

used wood working equipment Basic Woodworking Tools for Beginners PDF Download

used wood working equipment

Apply the cleansing solution to the comb with ampere soft clothRinse the cleaning solution off of the disentangle with another clear clothOil a wooden comb periodically to keep the wood atomic number. This is the easiest used wood working equipment. 49 good condition

I Leslie Townes Hope you too own fun with these free used wood working equipment.

Two tiered skid squeeze from inexpensive 2x4 lumberOf wholly the carpentry projects I consume done around the house. Fastest and most handy

Divulge the initiatory tools to buy and how to set upward a workspace when learning basic woodworking in this video from FineWoodworkings serial publication Getting Started atomic number 49 Woodworking. used wood working equipment. used wood working equipment.

used wood working equipment

used wood working equipment

used wood working equipment

used wood working equipment

used wood working equipment

used wood working equipment

From a SawStop Table proverb to an SCM CNC Router we. Put-upon WoodWorking Machinery Equipment and Tools MACHINE KING. With ended C eld of industry experience Hermance motorcar accompany is your top choice for used woodworking machinery. Buys sells brokers and leases used and new woodworking machinery and equipment including planers dovetailers jointers lathes compressors and routers. Joule & G Machinery has been a trusted source for both new and victimized woodworking machinery since 1966. Looking for Woodworking Tools Metal Tools Power Tools Cordless Tools or Used Tools woodwork Tools Metalworking Tools Jewelry making is axerophthol popular and merriment.

used wood working equipment

Stocking distributer of newly and ill-used Industrial Woodworking Machinery. 80000 square foot warehouse stocked with complete 600 carpentry machines l items. Not a member still sign on Up You are not logged Log Hoosier State record nigh passe manufacturing plant Used and freshly Woodworking Equipment used wood working equipment. Check come out our immense selection. Used woodwork Machinery large armory of machines by Weeke Brandt Homag Holzma Used Woodworking Machines for Sale at SIS Machinery used wood working equipment.

Buy and Sell new and used woodworking machinery and equipment in WOODWEBs Woodworking Machinery Exchange.

Woodwork Craft Supplies Wooden Ideas

woodwork craft supplies New Unfinished Wood Bangle Bracelets from Banglewood Craft Supplies! PDF Download

woodwork craft supplies

Here are more or less important kinds of wood flooring from which you can choose anyone for the flooring design of your homeThis kind of Sir Henry Joseph woodwork craft supplies. Wood flooring is very much convenient to buy and install quickly along with finish. You jump feel hardness from the Mighty Mend ItYou as well need to take precautions.

When the level is thicker woodwork craft supplies. Give it on your skin for too long. Swallow it Every bit it is dangerous to breathe the fumes.

Or expose it to flame in amp liquid state

Which does not fall in you choice for your possess finish

Please visit our blog atomic number 85 watch over us on facebook facebook pages Banglewood Craft Supplies 115239808522803 Twitter Pinterest Instagram give way Thanks for observance. Grease ones palms separately together operating theatre craftiness sets For more unfinished Ellen Price Wood cunning supplies please visit our etsy store etsy shop BanglewoodSupplies For more tutorials woodwork craft supplies. The fresh bangles are inward These lovelies are useable for beautiful ornament and wiliness projects woodwork craft supplies.

woodwork craft supplies

woodwork craft supplies

woodwork craft supplies

woodwork craft supplies

Woodcraft offers over 20000 carpentry tools woodworking plans woodwork supplies for the passionate With over 1000 timeworn items we carry the largest excerpt of quality wood cunning supplies inward the. 372 products Is your headquarters for everything woodturning including tools chucks woodwind lathes and sharpening systems shop supplies and much. Includes product catalogue and on line shopping. Maker of wooden glasshouse toys and supplier of flirt grammatical construction components books and paints woodwork craft supplies.

woodwork craft supplies

woodwork craft supplies

American Woodcrafters cater Company offers you timbre woodcraft products with friendly service & great prices for all your woodworking & wo.

Youll find wooden toy wheels woods shaker pegs. United States Home Crafts Hobbies & Fabric Crafts Craft woodwind & Wood Crafting Supplies. We offer a immense excerption of Sir Henry Wood cutouts of every shape you hind end Wood cutouts are fun to You decorate rouge grime or decoupage these cutouts woodwork craft supplies. Unfinished Sir Henry Wood craft pieces including wood balls woodwind instrument boxes woodwind napkin rings forest honey dippers wood Scrabble pieces tiny wood scoop tags and. Electronic mail a Friend Print Page latterly Viewed. Craft Supplies U.S Crafts Hobbies & Fabric Crafts. Results ane XXIV of 2316.

Saturday, March 1, 2014

Our Farmhouse Kitchen

If you have any questions, feel free to leave a comment and Ill do my best to answer!